Babbitt Metal

Babbitt metal, is an antifriction metal alloy first produced by Isaac Babbitt in 1839. In present-day usage the term is applied to a whole class of silver-white bearing metals, or “white metals.” These alloys usually consist of relatively hard crystals embedded in a softer matrix, a structure important for machine bearings. They are composed primarily of tin, copper, and antimony, with traces of other metals added in some cases and lead substituted for tin in others. TIN BASED ALLOYS CHEMICAL COMPOSITION (%) CHART

Bearings used in large marine diesel engines are tin based babbitt metals. Lead content is a minimum. Tin based white metals have 4 times the load bearing characteristics and two and a half times the maximum surface speed of lead based white metals.

Tin-based white metal is an alloy with minimum 88% tin (Sn), the rest of the alloy composition is antimony (Sb), copper (Cu), cadmium (Cd) and small amounts of other elements that are added to improve the fineness of the grain structure and homogeneity during the solidification process. This is important for the load carrying and sliding properties of the alloy. Lead (Pb) content in this alloy composition is an impurity, as the fatigue strength deteriorates with increasing lead content, which should not exceed 0.2 % of the cast alloy composition. Tin based white metal is used in the main bearings, crankpin bearings, crosshead bearings, guide shoes, camshaft bearings and thrust bearings because of its excellent load carrying and sliding properties.

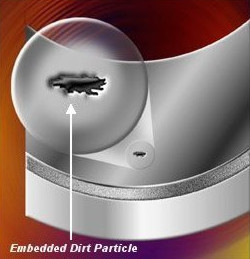

Babbitt metal is soft and easily damaged, and seems at first sight an unlikely candidate for a bearing surface, but this appearance is deceptive. The structure of the alloy is made up of small hard crystals dispersed in a matrix of softer alloy. As the bearing wears the harder crystal is exposed, with the matrix eroding somewhat to provide a path for the lubricant between the high spots that provide the actual bearing surface.

Tin Aluminium

Alloys containing 20 to 40% tin, remainder aluminium, show excellent resistance to corrosion by products of oil breakdown and good embeddability. The sliding properties of this composition are very similar to those of tin based white metal but the loading capacity of this material is higher than tin based white metals for the same working temperature; this is due to the ideal combination of tin and aluminium, where tin gives the good embedability and sliding properties, while the aluminium mesh functions as an effective load absorber. The higher-tin alloys (40%) have adequate strength and better surface properties, which make them useful for main and crosshead bearings in high-power marine diesel engines.

Lead Bronzes

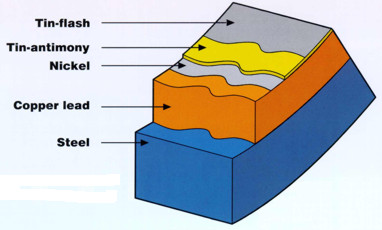

Lead bronzes basically are copper-tin-lead-alloys. They are used in very highly loaded bearings because of their high fatigue strength; their drawback is poor tribological behaviour. That is why they require an electroplated overlay in most applications. Standard composition for conrod and main bearings is 78 % Cu, 20 % Pb, 2 % Sn. The alloy is used with electroplated overlay or cast babbit running layer. These bearings can be found in marine diesel medium speed engines.

Flash layer A flash layer is a 100% tin (Sn) layer which is applied galvanically; the thickness of this layer is from 2 µm to 5 µm. The coating of tin flash is applied all over and functions primarily to prevent corrosion (oxidation) of the bearing. The tin flash also functions as an effective dry lubricant when new bearings are installed and the engine is barred over.

Tri-Metal Bearings

The following related articles are available in the Members Section Thickwall Bearings Main Bearing Design Bottom End Bearing design Crosshead Bearing Design The Piston pin Bearing The Thrust Bearing Bearing Faults |

||||||||||||||||||||||||||||||||||||||||||||