|

|

Operational Information

Fatigue

|

****JavaScript based drop down DHTML menu generated by NavStudio. (OpenCube Inc. - http://www.opencube.com)****

|

|

A

metal subjected to a repetitive or fluctuating stress will fail

at a stress much lower than that required to cause fracture on a

single application of load. Failures occurring under conditions

of dynamic loading are called fatigue failures, presumably

because it is generally observed that these failures occur only

after a considerable period of service. Fatigue accounts for at

least 90 percent of all service failures due to mechanical

causes.

Fatigue occurs when a

material is subject to alternating or cyclic stresses, over a

long period of time. Examples of where fatigue may occur in a

marine diesel engine are: crankshafts, valve springs,

turbocharger blades, piston crowns, bottom end bolts, piston

skirts at the gudgeon pin boss and tie bolts.

Stresses can be applied

in three ways, torsionally, axially and by bending.

The symbol for

stress is the Greek letter sigma s

and the units are force/ unit area i.e N/m2 or psi

(imperial)

|

|

TORSIONAL

This is where the

material is twisted and untwisted along its axis. Any

rotating shaft driving a load will be subject to torsional

vibration at the natural frequency of the shaft. However

torsional vibration is most easily visualised in an engine

crankshaft where the compression and firing forces are

applied to the crankpin through the piston and con rod.

These forces vary according to angle of

thrust applied by the conrod and the cylinder firing

pressure but are greatest at about 10° either side of TDC.

The

crank also has to absorb the inertia loading due to the

conrods and pistons, which easily amounts to several tons on

each cylinder.

|

|

|

AXIAL

This is where the

material is subject to tension or compression along its

axis. An example of this are the bottom end bolts on a four

stroke engine.

The bolts and their nuts are subject to

tensile stress when tightened and additional varying tensile

stress during operation. The total stress level is high and

varies with time, giving rise to the risk of fatigue. The

connecting rod is in compression during the compression and

power strokes, but due to the inertia forces in the running gear

when the piston changes direction between the exhaust and inlet

strokes, the connecting rod is put into tension. This increases

the tension in the bottom end bolts, leading to cyclic

stressing. |

|

|

BENDING

When

material is bent, the inside of the bend will be in

compression and the outside of the bend will be in tension.

This type of stress can be easily visualised in a piston

crown under the gas load and is compounded by the stresses

induced by the difference in temperature on the top surface

and the underside of the crown (thermal stressing).

It also

occurs in crankshafts where the gas load on the piston is

bending the crankshaft. If the main bearings are of

different heights (i.e out of vertical alignment), then the

bending is increased. |

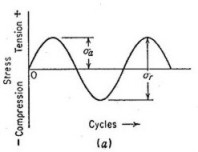

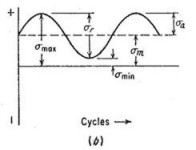

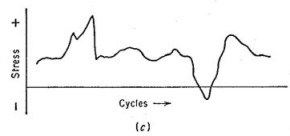

STRESS CYCLES

There are three stress cycles with which loads may be applied to the component

under consideration. The simplest being the reversed stress cycle . This is

merely a sine wave where the maximum stress and minimum stress differ by a

negative sign. An example of this type of stress cycle would be in an axle,

where every half turn or half period as in the case of the sine wave, the stress

on a point would be reversed. The most common type of cycle found in engineering

applications is where the maximum stress (smax)and

minimum stress (smin) are asymmetric (the

curve is a sine wave) not equal and opposite. This type of stress cycle is

called

repeated stress cycle. A final type of cycle mode is where stress and

frequency vary randomly. An example of this would be hull shocks, where

the frequency magnitude of the waves will produce varying

minimum and maximum stresses.

THE S-N CURVE

|

The S-N curve is just

a graph plotted of stress, S against the number of cycles N.

N is a logarithmic

scale i.e 105 cycles, 106 cycles 107

cycles etc.

The line plotted for the particular material will indicate

how many stress reversals it can go through before it fails.

If the material is loaded below the fatigue limit, which in

the example shown is 14×103 psi (95×103

kN/m2) then it will not fail

regardless of the number of stress cycles.

Material such as aluminum, copper and magnesium do not show

a fatigue limit, therefore they will fail at any stress and

number of cycles. Other important terms are fatigue strength

and fatigue life. The stress at which failure occurs for a

given number of cycles is the fatigue strength. The number

of cycles required for a material to fail at a certain

stress is the fatigue life.

|

|

CRACK INITIATION,

PROPAGATION AND FAILURE

Failure of a material due

to fatigue may be viewed on a microscopic level in three steps:

-

Crack Initiation:

The initial crack occurs in this stage. The crack may be

caused by surface scratches caused by handling, or tooling of

the material; threads ( as in a screw or bolt), flaws in the

material, slip bands or dislocations intersecting the surface

as a result of previous cyclic loading or work hardening.

-

Crack Propagation:

The crack continues to grow during this stage as a result of

continuously applied stresses

-

Failure: Failure

occurs when the material that has not been affected by the

crack cannot withstand the applied stress. This stage happens

very quickly.

|

|

Fatigue failure can

be identified by examining the fracture. A fatigue fracture

will have two distinct regions; One is smooth or burnished

as a result of the rubbing of the bottom and top of the

crack as it is growing. The second is granular, due to the

rapid failure of the material. |

|

Other features of a

fatigue fracture are Beachmarks and Striations. Beachmarks,

or clamshell marks, may be seen in fatigue failures of

materials that are used for a period of time, allowed to

rest for an equivalent time period and the loaded again as

in factory usage. Striations which can be seen through a

microscope, are thought to be steps in crack propagation,

were the distance depends on the stress range. Beachmarks

may contain thousands of striations |

|

|

Visible beachmarks on a

tiebolt failure |

Magnification of fatigue

failure showing striations |

|