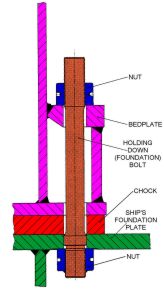

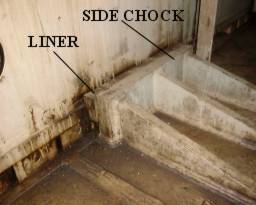

The engine is mounted on resin or cast iron chocks and bolted to the hull using holding down bolts. The engine must be securely fixed into the ship. As the engine turns the propeller, the propeller tries to push or thrust the propeller shaft and engine crankshaft forward into the ship. The thrust bearing which is situated at the aft end of the engine transmits this thrust from the crankshaft to the bedplate. The bedplate is mounted on chocks and is securely bolted to the engine foundation plate on which it sits and which forms part of the structure of the hull. The Engine must also be lined up with the propeller shaft. If the engine output driving flange was higher or lower, or to port or stbd of the propeller shaft, then it is easy to visualise that trying to connect them would cause bending stresses to be set up. The engine must also be bolted to a flat surface. If the surface was uneven, then when the bolts were tightened the bedplate would be distorted, which in turn would distort the crankshaft, causing unacceptable stresses to be set up when the engine was running. Before the engine is bolted down it is supported on jacks whilst it is aligned with the tailshaft bearing. This can be done by stretching a wire above the tailshaft and crankshsft, and measuring the distance from the wire to the crankshaft bearing centres. Modern methods use a laser.

|