In 1932 the Belgian Government cross channel service placed an order for a new vessel for their Dover - Ostend service. It was to differ from other vessels employed on the cross channel routes at the time, as it was to have a diesel engine main propulsion plant with electrical driven ancillaries and auxiliaries with power supplied from diesel powered generating sets. At the time the majority of ships were powered by steam, and even the motor ships of the time had a large steam plant to drive steam ancillaries and auxiliaries. The decision to build this motor powered vessel was for economic reasons. It was estimated that the saving in fuel would amount to £14000/ year (a not inconsiderable sum at the time) because unlike a steam powered cross channel ferry which had to keep her boilers fired and engines warmed through whilst in port, the Prince Baudouin would be able to shut down her engines in port and just run on the harbour generator.

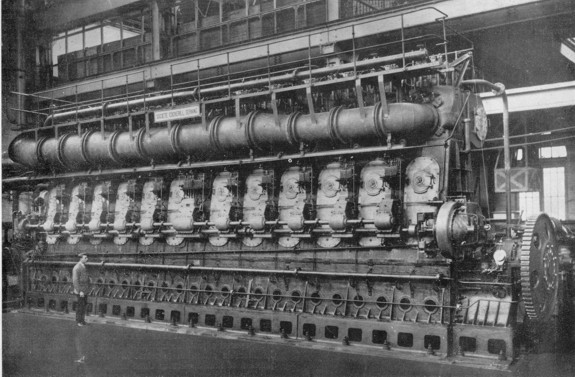

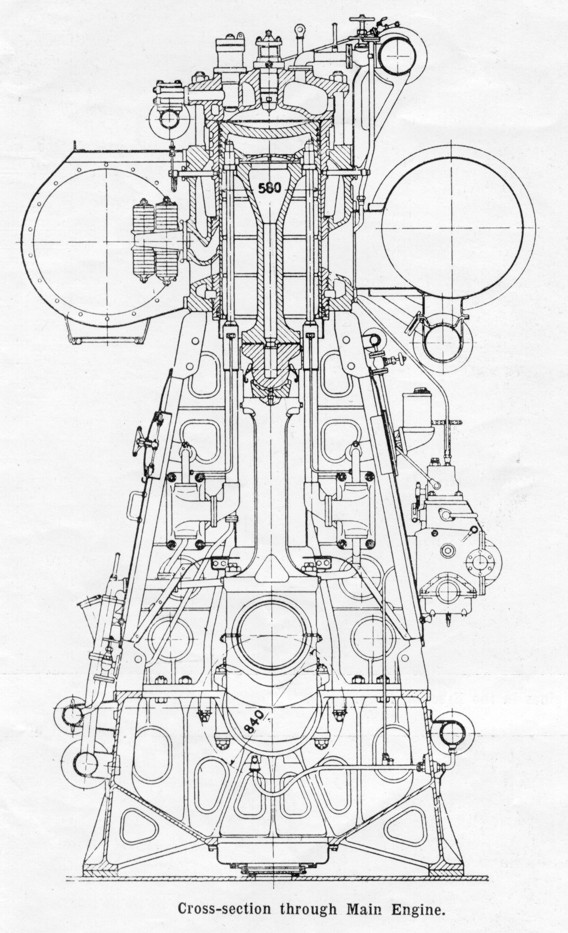

The main engines were Sulzer single-acting, twostroke cycle crosshead type, each engine having 12 cylinders 580 mm.(22.8in) bore and 840 mm. (33.1in) stroke. The engines were arranged for airless injection of the fuel.

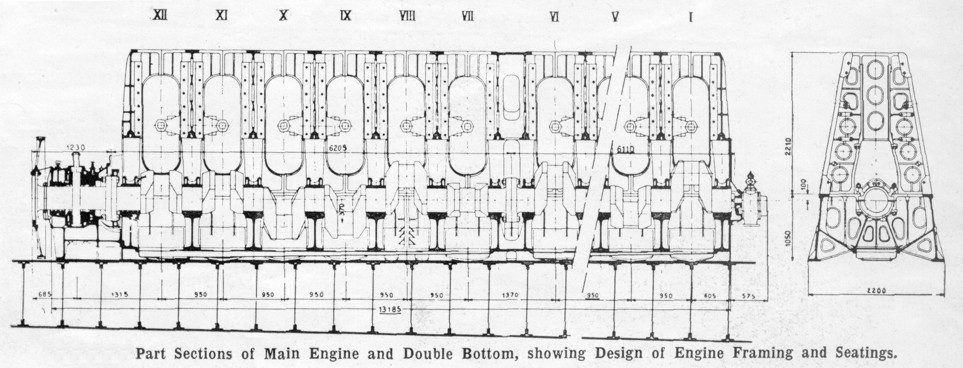

The engine dimensions were settled by the headroom available, which limited the stroke; and, based on this limited stroke, an engine speed, cylinder diameter and number of cylinders had to be chosen which would give a reasonable piston speed, an efficient stroke/bore ratio, and an efficient propeller. The overall dimensions of each engine were :-Length, 45ft.9in (13.95m) ; height, 15ft11.5in (4.87m); and width, 7ft.2.5in (2.2m).

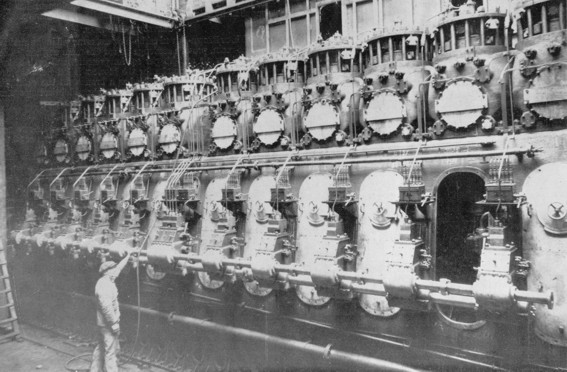

The fuel injection system consisted of a separate timed pump for each cylinder. The fuel supply was by gravity from overhead tanks. Starting air valves were only fitted to eight of the twelve cylinders, pneumatically operated from pilot valves timed by the camshaft. Starting air was supplied by two compressors at 420psi (28 bar) two two air receivers.

Cylinders were lubricated at six points around the circumference by mechanically driven lubricators. The main LO system consisted of two engine driven pumps and two electrically driven pumps each of 30 tons/hour capacity. Autoclean filters and Sharples purifiers were fitted.

The engine jackets and pistons were sea water cooled and the fuel injectors were fresh water cooled.

Mean indicated pressure was 87psi (5.8 bar) Mean Effective Pressure at engine brake was 77psi (5.1 bar) at maximum rated output of 8500BHP (6338.45kW) giving a mechanical efficiency of about 88%.

Fuel consumption was quoted at 0.344lb/BHP/hr (208g/kW/hr) LO consumption 0.00436lb/BHP/hr (2.64g/kW/hr)

The bedplate, framing and cylinder covers were of cast steel. The bedplate was bolted directly to a deep double bottom tank in which the frames and intercostals were welded to the top plate.

The auxiliaries were all electrically driven from power supplied by 4 main and 2 smaller generators with a total output of 2015kW. The scavenge air for the engine was supplied by three electrically driven blowers delivering air at 3.5psi (0.23 bar). These blowers absorbed almost 1500kW when operating at full load.

The Prince Baudouin was taken out of service in 1963, after which the vessel was used for a couple of years as an accommodation vessel in Zelzate (Ghent). The Prince Baudouin was scrapped in 1968. |